Seeing Sense in Local Manufacture: the Story of a Bike Light Made in Northern Ireland

So I'm riding around with these funky little high-tech lights on my bike from the Northern Ireland startup called See.Sense (see what I did with the blogpost title there?). The lights are rechargeable, feather-light, preternaturally bright, weatherproof, "intelligent," motion-programmable, and easy to attach to almost any bicycle, thanks to the magically stretchy and very secure rubber straps. Naturally, I attached these futuristic little darlings to the oldest bicycle in my possession. The front light looks surprisingly at home on its ancient fork-mounted headlight bracket!

I will say right off the bat that I am not the target market for these lights. Designed primarily for visibility (as opposed to illuminating one's path) and optimised to run in flash-mode, See.Sense lights are intended for urban commuters, for roadies who outstay the sunset, for cyclists looking to increase their daytime sparkle, or otherwise to be used as supplementary lighting. Me, I'm a "light up the road" kind of gal. And personally, I think flash mode should be outlawed (ducks, runs). Nevertheless, I still think these lights are darn cool and I can see why so many local cyclists are going nuts over them.

An absolute dream for gadget lovers, See.Sense lights have no on/off switch, or any switch at all for that matter. Instead, the lights activate via motion gestures.

These motion gestures are also used to program settings, making each light highly customisable. Features such as power output level, flash vs steady mode, motion sensing, and reactivity to light, can all be adjusted via a sequence of left/right rotations.

See.Sense lights are built with Fresnel lens elements to maximise angles of visibility, making the beam visible from the sides. And if that wasn't enough, the lights "continually monitor motion, orientation and light," responding to "road conditions - junctions, roundabouts, filtering in traffic, approaching headlights and more." The lights also react to the bike's orientation and speed. And an auto-standby feature puts them to sleep after 3 minutes of inactivity, activating them again when the bicycle is in motion.

Now, whether all of this sounds awesome or makes you want to plead for a simple on/off switch, probably depends on where you stand on the tech-loving spectrum. But for those who belong to the former category, I daresay at £80 per set the See.Sense lights are not a bad deal at all - considering all the features designed into them. And considering that they are locally made.

It was this aspect of See.Sense that intrigued me and made me want to pay them a visit. Northern Ireland is not exactly bustling with industry, making outsourcing the obvious choice for most NI-based inventors and designers. How then did this small, fledgling company manage to get a niche product such as bicycle lights produced locally?

The answer is NItronica. Located on an industrial site in the otherwise rural Ballynahinch, it is just 15 miles from the See.Sense office in Newtonards. Both locations are fairly close to the outskirts of Belfast.

When I asked whether I could visit the factory to see how their lights are made, Irene and Philip of See.Sense agreed in the sort of casual, lighthearted manner that made me envision I would be dropping by and taking some snaps, with no one paying me any mind. But as the visit drew nearer, planning grew more elaborate - so that in the end, the visit took on the formal and exciting feel of a government delegation, complete with tea, sandwiches, a presentation and a tour.

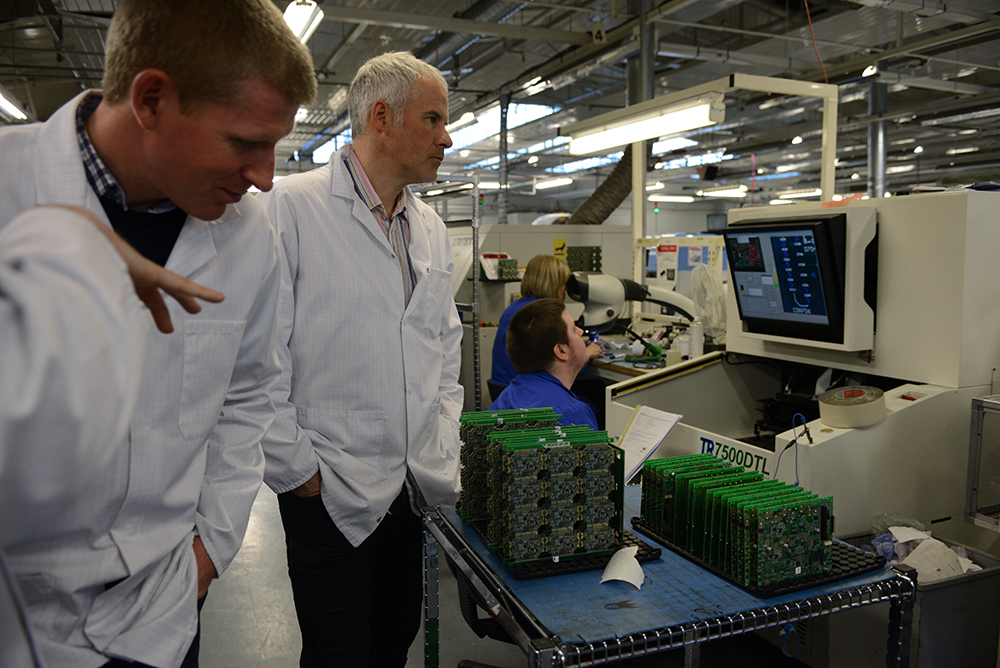

Rather than sneaking around incognito, I was part of a group that included cycling wonder-coach Dave Smith (aka ffflow), and a group of brand-new employees and interns at See.Sense who had yet to visit the factory.

In the first instance we were treated to an interesting talk about the factory's manufacturing practices and history. NItronica as it is known today came into existence in 2002, when some former employees bought out the failing telecommunications company Viassistance that had occupied the site for decades prior.

Specialising in the manufacture of electronics, the range of products NItronica are capable of producing is surprisingly diverse - from cotton candy machines,

to parts for underwater turbines,

to - well, bicycle lights!

Business proved successful, and NItronica now have many clients throughout the UK and Ireland, continental Europe, and some even further afield.

At the moment, NItronica employs a staff of 135, a good portion of whom we had a chance to meet and briefly speak to.

But before we did any of that, we were required to go through the rather exciting process of donning white lab coats and strapping heel grounders onto our shoes. We then took turns going through an electrostatic discharge tester to ensure the grounders were working properly, before finally being let loose onto the factory floor.

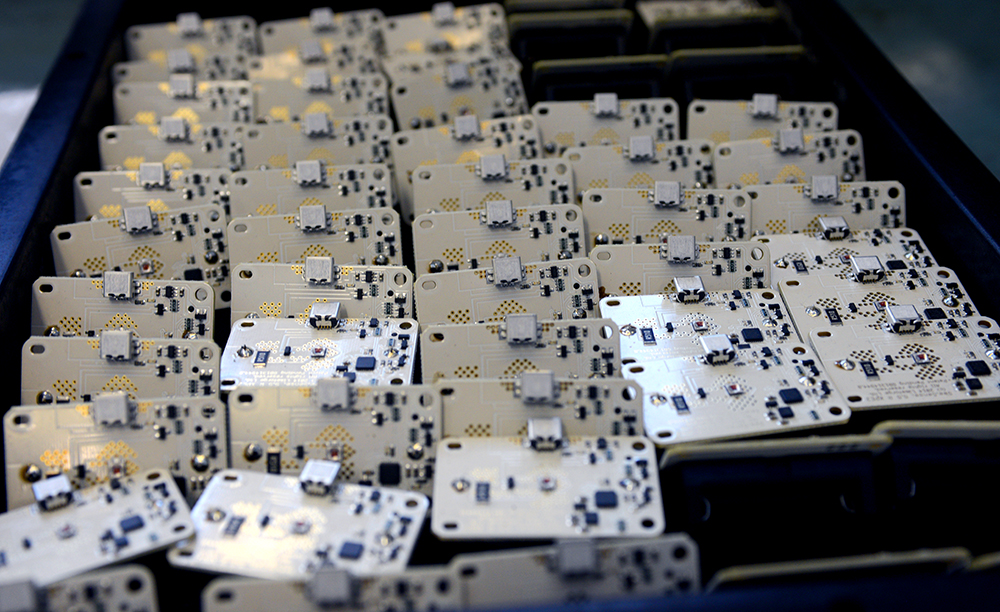

While the details of manufacturing See.Sense lights are top secret, in a broad sense it involves making circuitboards and shells for those circuitboards.

The circuitboard manufacturing process involves soldering chips onto ribbons and boards.

This is done via a multi-step machine process.

At the end of which the boards are cut into light-sized segments.

At this stage, finishing touches are done by hand.

Which is followed by several testing and quality control phases.

Again, involving both machines and individual attention.

Finally, the innards are prepared to be assembled into lights.

(As our delegation has determined, the lights do not work without the crucial assembly phase.)

Not to worry though, as assembly takes place in the factory also - albeit a lot quicker when we are not there to pester the employees.

As interesting as it was to visit the NItronica factory and see how See.Sense lights are made, what I found more interesting still was the company's response to my question of why they chose to manufacture locally.

To my surprise, the answer to this question was that it made the most sense financially. When the founders of See.Sense were first looking at where to have their product made, they did research and compared the available options. Having discovered there was a factory capable of making their product in their own backyard that was willing to do small batch production while also being capable of going large-scale, they compared prices, did a cost/benefit analysis, and determined that going local simply made more sense in their case. NItronica's cost was reasonable. Their reputation was excellent. And, just as importantly, the factory's proximity would facilitate communications, eliminate travel expenses, reduce manufacturing time, allow for greater involvement in and control over the manufacturing process, and offer greater flexibility.

As all this was being laid out for me, it made perfect sense. It was, however, quite a change from the more typical story I am accustomed to hearing- that of how much more difficult and expensive it is to manufacture locally than to outsource.

And indeed, for many companies it is more difficult and more expensive to manufacture locally - sometimes so much so that going that route is financially impossible; by no means is my intent to invalidate this claim. But what I mean to say is, "locally made" does not automatically mean mission impossible. And a business isn't always forced to chose between wishing to make a reasonable profit and opting for local production. It all depends on the industry, on the location, on the specific logistics involved in manufacturing a particular product, and on many other individual factors.

Talking to See.Sense and NItronica about their practices has offered me a new perspective on local manufacture, which I hope you too might have found interesting. And while I will be returning my sample lights soon, I will continue to follow See.Sense with interest. Aside from being a downright adorable couple, Irene and Philip are doing cool, innovative things and are a pleasure to talk to about cycling, technology, and pretty much anything else. I look forward to seeing what else they come up with in future, and I thank them for taking the time to speak to me about their products and show me their manufacturing process. A thank you also to NItronica for the informative tour.

See.Sense lights (and bio waterbottles!) are available for purchase through their website and via online retailers. Full pictureset can be viewed here.

I agree wholeheartedly with you about outlawing flashing lights, particularly after dark!

ReplyDeleteThis looks like a remarkable product, all the more impressive given that it's made locally (to you!) and not prohibitively expensive.

However, my recent experience with a Luxos U headlight made me pine for a simple on-off switch indeed, and that is what I returned to using as a result. I wonder if See.Sense might consider a less-expensive follow-up using the sophisticated Fresnel lens but without all the electronic wizardry. Reliability is by far the most important thing in bicycle components, and lights involving microchips have usually disappointed me in that regard.

As I understand it, the rationale to not having an on/off switch is that it virtually eliminates chances of the light breaking (I am told this is where most faults/damages occur). When it comes down to it, I think for most people it's a matter of trust - some "trust" the microchips, the motion sensors and the rotation-based programming, while others need that manual obvious on/off.

DeleteOutlawing flashing lights while vehicular homicide occurs at alarming rates.

ReplyDeleteLet's see, the reason they are annoying is b/c they get attention away from phones, robot drivers, drunk drivers, voice recognition fails, soundproof cars. Have you even ridden in a new car with all this going on?

I light my wife's bike like a Christmas tree; she's been told many times by drivers that they appreciate her effort at standing out in a chaotic environment. But go ahead and wish they were outlawed - if even one rider dies well at least you aren't annoyed.

Hey. I ducked AND I ran, come on.

DeleteThe pro/anti flash is a valid ongoing debate, both sides being concerned for safety. Not going to go into it here, but perhaps a dedicated post sometime.

My very adequate Busch & Muller lights have no flash mode for the simple reason that flashing lights on a bicycle are illegal in Germany. As they should be. Flashing lights are a distraction and a hazard for all other road users. At the extreme there are now cyclists riding around with strobe lights (not flashers) so bright they are simply blinding, even at midday in midsummer. The riders who want to mount these things always aim them up as high beams. I don't know that it is even possible to correctly aim a headlight while riding in daylight hours.

ReplyDeleteThere is no reason whatever for a cyclist to mount a headlight in daylight. Cyclists have better forward visibility than anything else on the road except pedestrians. Cyclists have far more scope for taking evasive action than do pedestrians. A cyclist who gets hit from the front is a cyclist who was asleep. Self-preservation is your responsibility. It is not a task you can fob off on others.

Worst is coming around a corner and facing a flock of strobes. I regularly pull off the road in this circumstance. Cyclists mounting these devices seem to take glee when they force cars to make dangerous stops en masse. Increased daytime sparkle is more properly termed reckless endangerment. As such there are statutes against this nonsense everywhere and I sincerely wish traffic cops would start arresting cyclists who participate in this delusion. Anonymous on this comment only for technical reasons. I own this comment as John C. Wilson. Four hundred thousand road miles, two minor accidents involving motor vehicles. Both accidents caused by motorists travelling the wrong way in a oneway AND making sudden last moment moth-to-a-flame maneuvres seeking to hit me. Both drivers drugged to the gills and no light would've made the slightest difference.

Okay. As above, I will say this is not the time/place I wish to host this debate.

DeleteNo more comments in this genre and tone please.

OT, but I am curious: Did you ask the Nitronica employees to pose for you, or did they strike those poses spontaneously? As a fledgling photog I would love to know what methods you use to put strangers at ease.

ReplyDeleteWell I have several methods in my arsenal. A favourite is to make ventriloqual animal noises and catch them by surprise.

DeleteNo. I did not ask the factory staff to pose for me. In fact I had intended to photograph them working (and failed!).

I think you did an amazing job at photographing the NItronica employees and factory. I can see these photos in a company brochure.

DeleteHa. Thanks!

DeleteFactory Tour? Yes Please! Tea and Sandwiches? Absolutely!

ReplyDeleteFactory tours are THE BEST, JERRY, THE BEST! I have so many fantastic memories stretching back to my very first one, a pretzel factory in Lanc. Pa. when I was 5 where I got to eat all the pretzels I could hold! Plus 1! IN 1969! I bet I've averaged one a year since then and I don't remember a dud in the bunch.

I've toured a Forklift Plant, Car and or Truck Plants, Ammunition, Fertilizer and Pharmaceutical Factories, Plastic Film Factories(Cast AND Extruded), a Cigarette Paper Factory, Candy Factories, Poultry Plants, The old Con-Agra Ranch-Style-Bean Cannery in Texas from whence came 25% of my childhood nutrition, Aircraft Engine Re-Building Facilities(2), Propeller Factories(3, Hartzell, Hamilton-Standard AND Sensinich). I've seen Chicken Franks sailing out of the Frank-O-Matics at the Esskay plant in a huge glistening pink parabola at a rate and volume that would tear your head off if you took your chances and stepped over the chain, saw glowing dinner plates conveyering out of the kiln from the corner of my eye at the Corning Glass factory while pretending to listen to the perky tour guide whose blouse I was practicing my X-Ray vision on in the summer before my 8th grade year. I got hollered at in the sampling area for filling a paper sack I smuggled into the Herr's Snack Factory tour that same year, and was so touched by being chosen to receive the single Baseball presented to a member of the tour of the Rawlings plant that I dropped the one I had already stolen behind a soda machine on my way out.

I took a girl I met at a track meet in College on a date to the Hershey Chocolate Factory in Hershey Pa. a thousand years ago, figuring on getting SOME kind of Kiss out of it but having to be satisfied with a not quite full-sized souvenir Mr. Goodbar and a hand shake at the end of the day. Fail. On a dare I endured 2 of the tours(Including the eviscerating line, Bbrrr) they used to give prospective employees of the Poultry Processing plant in Dayton Va.(I don't recall which giant multi-national owned it at the time) because I was trying to meet the woman from their H.R. Dept. who lead them. Failed. Chose the tour of the Dr. Pepper plant in Waco in 10th grade over the trip to the Car Museum hoping to get in Letty Cruz's bubble. Failed. Broke that streak when I toured the Old Armory(not technically a factory but close enough) at Harper's Ferry with a woman I was chasing and ended up wishing the streak had held.

Factory tours are pretty wonderful, where else could a young kid get a good look at America's commercial might, the drudgery awaiting those who neglected their studies and the acres of soft-core pornography inside the lids of toolboxes and the doors of storage lockers all in one day. Nowhere, that's where.

Spindizzy

Oh yeah, I hope you managed to steal a head light or a cotton candy machine or something...

I tried to steal the underwater wind turbines but overestimated my improvements in upper body strength.

DeleteVery interesting and nice to see a company manufacturing a quality product locally. I personally don't use lights on my bike at all, though if I lived in a rural area with quiet roads I would - the thought of cycling along a country road at night sounds so enticing but here any roads that are out of town are bush trails which could be rather hazardous in darkness even with strong lighting. I actually like the idea of a light with no 'on/off' switch provided it is not difficult to program and maintain.

ReplyDeleteThe only comment I'm going to make is this. I'm sure, it gives you a sense of pride to see a product manufacturerd in your homeland by your follow countrymen.

ReplyDeleteBe it the U.S. or Ireland, sometimes it's nice to see an affordable product that isn't made in China.

Just Saying.

Well it's not my homeland, I'm a foreigner! As is 1/2 of See.Sense itself : )

DeleteI have a post here from a few years back about things being made in China and what that means. If I can manage to find and link it, the comments from manufacturers are quite interesting. One thing worth noting is that China is not the name of a factory. It is a large country with many factories, which differ in their production methods, wage policies, environmental policies, etc. Company X and Company Y can both be producing in China, yet making their products very differently. Another thing to consider is that outsourcing is not always done because it is cheaper. Depending on the product/industry, there may no longer be any local expertise and infrastructure capable of the required production and volume. Lots of other factors involved here, point being that things are not black and white as in outsourcing=bad, local production=good.

That said, See.Sense makes for an interesting case study where, all things considered, local production isn't just feasible, but is the best option.

^ Here is the link to that post:

DeleteWhere Was Your Bicycle Made? and Does It Matter?

Cool. I don't mind the lack of an on/ off switch nor the flash mode. Thanks for featuring this interesting company.

ReplyDeleteRufus

available in the US?

ReplyDeleteNot sure whether any American retailers carry See.Sense yet, but shipping to the US is relatively painless via Chain Reaction.

DeleteI love to see companies hiring and manufacturing locally where ever they may be. It must be heartening for people to find interesting work in an area that might not have much in the way of employment. And yes, many manufacturers have bitten themselves in the bum by outsourcing manufacturing offshore etc. The reasons for moving manufacturing to poorer countries were only possible because of poverty, lack of environmental laws, lack of work safe laws, lack of worker rights, lack of democracy etc.. China was opened up for business at any cost. We demanded or were told to demand cheaper goods, and so the cycle began of ever cheaper goods 'from China'. Yet, China is a rising economy and the fastest growing luxury market. People will demand better wages, environmental, health and safety regulations which will drive up costs, and the cost of shipping etc. There is also the issue of lost in translation, companies having issues with something going very wrong and unable to fix it because head office could be in Portland or London and nobody there knows what happens at the factory. Loss of quality control, loss of any control for that matter. The fiasco with Lululemon's very thin pants was due to a simple mix up in the manufacturing instructions.

ReplyDeleteSome companies are returning manufacturing closer to headquarters and the market region to regain quality control etc..

Yet because Asia is such a rising market, we in the west may never see those jobs again. Asia has the infrastructure, the technology, the educated/skilled work force and best of all, they do not have to send the product on ships across oceans!

As the for light it looks sweet and and interesting, might be a great rear light. I personally need lights that light up the road.

Some business managers are starting to weigh the costs and benefits of local vs. offshore production by including the speed at which improvements in design and manufacturing can be achieved. Nobody fixes a problem they can't see. Ideally design and manufacturing staff are in tight communication, each group challenging the other to do better. (Japanese manufacturing experts call sending engineers and managers onto the production floor "going to Gemba". Gemba, or Genba, is "where the value is produced".) Faster iterations mean your product gets better and cheaper than the competition over time.

ReplyDeleteGreat job on the article and on the photos! My favorite is the one of the gentleman in the blue coat holding a caulking gun. His expression is how I feel when riding (and about local manufacturing, too)!

ReplyDeleteI see that the lights got a good review from bike tech guru DC Rainmaker.

ReplyDeletehttp://www.dcrainmaker.com/2015/10/hands-smart-lights.html