A couple of weeks ago I visited

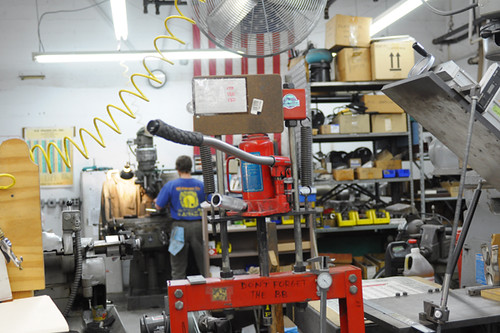

Seven Cycles - a local manufacturer of titanium, steel and carbon fiber bicycles. I was given a tour of the factory and it was, of course, fascinating. I never tire of seeing local framebuilding shops: The machinery, the precision of the work involved, even the heaps of tubing and the scraps of metal lying around excite me. And there certainly was all that at Seven, on a grand scale.

To my surprise - seeing how they are TIG-welders mostly - there was even lugwork.

Lots and

lots of lugwork in fact, with interesting cutouts.

But what made the biggest impression on me during the visit was not the intriguing floor layout, the delicately carved titanium latticework, or the explanation of Seven's approach to the manufacturing process. It was the fact that I recognized so many of the faces I saw there.

It is hard to explain the state of mind this put me in without coming across as preachy about local manufacturing, which is not my intent. I am not thinking about the political-economic implications of local manufacturing as a concept, but about the very concrete existence of

my local manufacturing. I mean, there is a factory 6 miles from my house, and in this factory they make bicycles from scratch, and the people making these bicycles - well I happen to know many of them and they live nearby, and sometimes we even see each other on the street. That is highly unusual is all. In today's society the relationship between objects and the people who make them has become completely abstracted. We do not expect our neighbours to make the stuff we might be using; we expect that stuff to be made by some nameless entity, far away from our little world.

When I told Seven owner Rob Vandermark how much I enjoy watching frames being built, he replied that not everyone feels that way. For some seeing the process takes away the mystery, and it's more exciting if a frame just "appears" - shiny and new with flawless paint. I've heard that before. A framebuilder once told me that he discourages customers from watching him work, because it makes them more aware of the possibility of human error and later those customers are liable to feel more nervous about their frames. Psychologically, that makes sense. But it also means that consumers of goods prefer

not to think about the process of making those goods, which has all sorts of far-reaching implications.

Maybe it's because I've made things by hand myself and used them, as well as given and sold them to others who've used them. But seeing how something is made excites me rather that ruins some illusion of flawlessness.

The first person I saw when I entered the production area during my visit was Bryan Hollingsworth of

Royal H. Cycles - whom I watched

make a lugged mixte frame for me more than 2 years ago now. He works for Seven (making carbon fiber frames!) a couple of days a week, and on Royal H. the rest of the time.

Welder

Mike Salvatore has his own project on the side as well, albeit a

Sketchy one.

Dan Pugatch lives in Somerville and is well known on the local cycling scene.

Dan writes a

blog and contributes to

Boston Retro Wheelmen, but what I didn't know is that he also has this cool tattoo that promotes cycling to work in regular clothing. Notice that the pirate is riding a step-through with a full chaincase. I wonder how the crate is attached to the rear rack, and whether there is a sword peg brazed onto the frame?

Jonathan Henig lives maybe 5 minutes from me and is a fellow photographer. First thing he did when we started talking was examine my camera lens and nod approvingly.

I had not met Neil Doshi before, but I knew

his bike - a happy marriage of titanium, green canvas and leather.

And now I saw it in person, along with dozens of other contraptions in the famous Bike Room. The bikes of Seven employees are staggeringly practical - lots of upright 3-speeds, handmade racks, huge saddlebags. More what I would have expected to see at Rivendell than at Seven, a company known for its racing bikes.

After my tour, I couldn't help but wonder whether I'd gotten the most out of it. The space is truly impressive and there is a positive energy that makes me want to run out and apply for a job there, regardless of what it is they'd assign me to do (I hear there is a

titanium shavings sweeper position open?). In retrospect I should have asked more detailed questions about the manufacturing process. I should have taken close-up photos of the machinery with a medium format film camera. Instead I walked around talking to everyone, then watching them quietly, then talking some more. Not necessarily about bikes either. And then we all said "good-bye" and "see you soon" and then I rode my bike home - an idyllic route from Watertown along the Charles River Trail.

Cycling home after my visit, I remembered the first time I met Rob Vandermark. It was about a year and a half ago, when I had just

discovered the Ride Studio Cafe. The first time I came in there was this tall, polite, unassuming guy serving coffee behind the counter. Naturally, I thought he was the barrista. Later someone came in with a flat tire and he went to take care of that, so then I figured he was the all-around shop guy. After a brief chat, it also turned out that he was my neighbour - living nearby in Somerville and commuting to Lexington by bike when possible. Only well into another conversation with him later did I learn, with some embarrassment, that he was the owner of both RSC and Seven Cycles. As a customer, you would never know. And of course the whole point is that it should not matter.

I guess all I'm saying is... My neighbours build bikes. And I think that's really, really great.

Greater Boston has an awesome framebuilding/fabrication scene. Lots of amazing hand built bikes -

ReplyDeleteSeven

Sketchy

Royal H

Geekhouse

Firefly

Ant

Igleheart

Parlee

Independent Fabrication (they are now located in New Hampshire but were, until recently, in Somerville).

I'm sure I'm forgetting a few.

Don't forget Peter Mooney in Belmont. And the new guy on the block, Tomii Cycles. Icarus was until recently sharing a studio with Royal H, but has now moved to (I think) North carolina. Let's see... there is also Ted Wojcik nearby in NH. and Peter Weigle in CT. Oh and of course the "ghost builders" - Cantabrigian Mechanics - are soon launching their own line, Commonwealth Bikes.

DeleteOops, forgot Armando of Quiros Cycles!

DeleteInteresting, what purpose does the lugs serve? do they both lug and weld the same connections?

ReplyDeleteI believe they are for carbon fiber frames with titanium lugwork. They've been making them for some time, but never with lugwork this nice and intricate.

DeleteIs a visit to Worksman in the offing?

ReplyDeleteWhen I finally make it to NYC again, definitely. Hopefully this Spring/Summer.

DeleteAgreed, really kinda cool!

ReplyDeleteDuring recent visit to NE Portland I happened upon a local brewery and above the bar hung frames from many, but not all, the local builders. I was stunned!! So cool, local beer and bikes all in the same place :)

Gosh, those lugs are beautiful!!! Do they paint the tubes? I am picturing a pale blue frame with contrasting while lugwork...

ReplyDeletesorry! white lugwork :))

DeleteI know a lot of customers prefer to keep the frames raw, but they will certainly paint it if you want, and contrasting lugs should not be a problem. They do the paint inhouse; it was cool to watch that as well.

Delete"...he discourages customers from watching him work, because it makes them more aware of the possibility of human error...Psychologically, that makes sense."

ReplyDeleteIt didn't bother me! I bought a custom bike from Dave Anderson (St. Paul, MN). He sent me scads of photos, from the pile of raw 953 pipes to the finished frame.

At one point, a photo showed the assembled frame, with the caption "Can you believe I'm about to cut this in two?" Sure enough, the next photo showed him cutting through the top tube in preparation to installing S&S couplers.

It's a matter of trust.

Ed in NH

I'd much rather see someone making the bike I'm about to ride than the sausage I'm about to eat ;>) The closest framebuilder to me is Bilenky (I think) and he's not that close, certainly not walking distance. I'd love to see how he makes a frame but I know I can't afford one of his frames so I'd rather not bother him. I envy you.

ReplyDeletewhat i like about this post is its subjectivity. there are other articles about seven cycles that offer information about the company, but only you are in a position to write something like this.

ReplyDeletei also appreciate that you do not go overboard and wax lyrical about the quivering veined hand of the loyal employee as he grips the blowtorch...

a good read.

Thank God I edited that part out. But also, they wear gloves, so I couldn't tell if the quivering hand was veined or not...

DeleteThe part on some customers preferring not to see what goes on because it makes them think of human error is interesting. I make homebrew and have a couple friends who are always a bit unsure about it even though they know I've personally had some of each batch.

ReplyDeleteLet me just clear my throat... um... YIP, YIP, YAHOOOO!

ReplyDeleteIf there is anything that is going to save this country from ruin, it is local manufacturing. Hats off to this Seven guy and what he is doing.

I know I'm a throwback, a dreamer, but I build guitars in my shop out back. I shipped one to Belgium, and I'm shipping them all over this country, and someone drove over from Houston and picked one up. You young people reading this blog, make something! Use your business degree to start a business that makes something, anything. I'm not anti-Chinese, I'm pro local manufacturing.

I love building stuff and places like SEVEN are so incredibly inspiring. The learning curve sometimes seems so steep with some things that it takes a visit to where this stuff happens everyday to give a guy like me the confidence to keep climbing.

ReplyDeleteI also agree that it matters a lot where and by whom some of the things that are important to me are made. I don't really care where my washing machine came from or who sewed my clothes as long as they aren't being screwed over in some sweat shop, but Bikes, Tools, and things I'm going to keep and use a lot for the rest of my life? I care.

I still have a French Horn even though I haven't played in a serious way since college and selling it would buy a better bike than I've ever owned. It gives me so much satisfaction to get it out and "play". I wouldn't sound any worse on a Conn or a Yamaha but I really appreciate the fine craftsmanship and the connection(tenuous but real for me) to the very best players over the last century who chose to play instruments from the same shop. I even know the names of some of the craftsmen who would have been making these horns 50 years ago when this one was put together.

We ennoble ourselves and honor others when we recognize the work and care put into things that were built to be as fine and good as could be made. It certainly isn't the most important thing in the world to be aware of but it makes a difference. I think it's dumb to fall into the trap of believing that "Only the very finest of everything is good enough for ME", but a few very fine examples of the particular things that we are able to appreciate and really use can make life nicer. The rest of the inventory can be cheap or indifferent but the important stuff ought to make us glad to have it.

And we should be willing to pay enough so that the Women and Men who make it can buy wine for their children.

End of Sermon.

The Rev. Spindizzy

"I think it's dumb to fall into the trap of believing that "Only the very finest of everything is good enough for ME", but a few very fine examples of the particular things that we are able to appreciate and really use can make life nicer. The rest of the inventory can be cheap or indifferent but the important stuff ought to make us glad to have it."

DeleteAt some point I experienced that revelation. There are some things that, let's just say most people I know consider necessities, but I could not care less about. I spend as little money on them as possible, or don't own them at all. And there are other things that I do not mind blowing my entire savings on if that's what it takes. It's all about personal meaning. All too often, we let society dictate what's necessary to spend money on and what's frivolous, but it does not need to be that way.

"even the heaps of tubing and the scraps of metal lying around excite me"

ReplyDeleteIf only I could get my wife to think like that!!!

Ok now you have gone and done it again! I'm green with envy, and St. Patricks day is TOMORROW. At least you could have sat on a Kelly green one for the camera.

ReplyDeleteAll teasing aside, there is always a certain beauty and value in a thing well made.

There were no finished bikes to pose with on the premises! But how's this for green?

DeleteI have read about the sad demise of Raleigh's Nottingham factory during the 70s. My wife and I own four bikes that were manufactured in that giant factory, which closed in part because labor was much cheaper elsewhere in the world. It's inspiring to see small manufacturers like Seven and Ant carving out a niche in the market.

ReplyDeleteLove Seven's new lugs, very clean and art deco. Are there pictures of the finished frames?

ReplyDeleteNot that I've seen. But I'll be sure to take photos if any arrive as RSC floor models.

DeleteYeah, check out the Seven website, also the 2012 brochure.

DeleteThis is a fascinating post, and your photography really brings out the relationship between the mechanical and the human. I think that's such a strong attraction for us to bicycles in the first place.

ReplyDelete+1 on loving those lug cut outs!

ReplyDeleteI am hoping to pull the trigger on an Axiom SLX this summer and would love to visit the factory (I am 30 miles down the road). Do you know if this is allowed, or are you one of the privileged few?

ReplyDeleteI know they give factory tours all the time, but I am not sure what their policies are. Best to contact them and ask.

DeleteArticles like this make me laugh. I worked at Seven for a couple of years. The quality-of-life of Seven employees is terrible. Ask an employee what Seven does in terms of continuing education or a retirement plan. Ask them if they receive paid-vacations. Ask a production worker if any precautions are taken to minimize the dust created from cutting and milling carbon fiber. Every article I read about Seven is so misleading. I'm glad I never bought a frame while I was there; couldn't afford it anyway, as their employee purchase program is almost nonexistent.

ReplyDeleteSurprised to read your comment. The people I know who work there (or have worked there in the past) have good things to say about both the working conditions and the employee purchase program. Don't know about paid vacations, but hey I don't get those in my line of work either.

Delete